Rapid Surface Graphitization of Carbon Anode for In Situ Regeneration of Batteries

11/2024, DOE-ARPAE

HighT-Tech will develop ultrathin and compact protective coating material for the graphite surface using Pulse Heating technology. The technology would enable in situ lithium iron phosphate/graphite battery cell regeneration and lengthen the lifetime.

Since lithium iron phosphate/graphite cells are relatively low-cost to produce, recycling the cells is prohibitively expensive. In this case, generating the battery, which recovers or restores the battery’s capacity, could be a more efficient and sustainable solution. This technological advancement would support the expanding $15 billion lithium iron phosphate/graphite battery market.

Scale-up the UHS Manufacturing for Solid-state Electrolyzer to produce Hydrogen

11/2024, DOE-EERE

HighT-Tech is leading a new $ 6.7 million DOE project with West Virginia University and Yale University to scale up the UHS manufacturing of solid-state electrolyzers for hydrogen production.

The grant from DOE underscores the significance of HighT-Tech's technology in addressing the challenges of high-temperature manufacturing. Leveraging our cutting-edge technologies, HighT-Tech aims to develop innovative manufacturing to reduce processing time and energy consumption, support local economic growth, and invest in workforce development.

HighT-Tech Scale-up the UHS Manufacturing of Solid-State Batteries

09/2023, DOE-AMMTO

HighT-Tech is participating in a new $4 million DOE-EERE project, teaming with Argonne National Laboratory (ANL) and Oak Ridge National Laboratory (ORNL) to scale up the UHS manufacturing of oxide-based electrolytes and solid-state batteries, which are intrinsically nonflammable.

The project will transform the current batch process for fabricating and sintering solid oxide-based electrolytes into a continuous process. This project will also integrate the NMC cathode, electrolyte, and anode into full cells and scale them up from the current button cell (≤10 mAh) to ≥ 1 Ah and ≥350 Wh/kg.

Scalable Manufacturing of High-Entropy Alloy Catalysts for Ammonia Oxidation

02/2022, DOE-ARPAE

HighT-Tech is leading a new ARPA-E OPEN 2021 project with the University of Maryland and Johns Hopkins University to create scalable manufacturing processes of high-entropy alloy catalysts (HEA) for ammonia oxidation with enhanced catalytic activity, selectivity and stability.

The catalysts can potentially reduce the use of precious metals, enhance energy efficiency, and improve the economic and environmental impact of chemical industries.

UHS Rapid Sintering Wins a 2021 R&D 100 Award

11/2021, R&D WORLD

Our study on UHS rapid sintering (Science 2020) has won a prestigious 2021 R&D 100 Award in the Process/Prototyping category.

Established in 1963, the R&D 100 Awards is the only S&T (science and technology) awards competition that recognizes new commercial products, technologies and materials for their technological significance that are available for sale or license. The R&D 100 Awards have long been a benchmark of excellence for industry sectors.

HighT-Tech’s Innovative Approach to Catalyst Development Wins The Spinoff Prize 2021

07/2021, Nature

The Spinoff Prize 2021, a Nature Research Award has been awarded to HighT-Tech for its next-generation discovery platform to address an important technical bottleneck in industrial catalyst development.

HighT-Tech proved itself as a company with world-class scientific foundations. The technique to use alloys addresses the technical and expensive bottleneck the sector currently faces, significantly reducing the risk of technological or commercial failure.

New Environmental-Thermal Barrier Coatings for Ultrahigh Temperature Alloys

11/2020, ARPA-E

HighT-Tech is participating a new ARPA-E project with the University of Maryland to leverage a newly invented, ultrafast high-temperature sintering (UHS) method to perform fast exploration of new environmental-thermal barrier coatings (ETBCs) for 1300°C (2372 °F)-capable refractory alloys for harsh turbine environments.

UHS enables ultrafast synthesis of high-melting oxide coatings, including multilayers, in less than a minute, enabling rapid evaluation of novel coating compositions. By using UHS with fast-fail tests and modeling and analytics tools, the team will be able to explore hundreds of compositions and coating architectures to design and optimize 1700°C (3092 °F)-capable ETBCs with different layer sequences, thicknesses, porosity levels, and novel compositions.

High-Entropy Alloy Catalysts Wins a 2020 R&D 100 Award

09/2020, R&D WORLD

Our study on high-entropy alloy catalysts (Science, 2018) has won a prestigious 2020 R&D 100 Award in the Mechanical/Materials category.

This renowned worldwide competition, now in its 58th year, received entries from 19 countries and regions. This year, the judging panel expanded to include nearly 50 well-respected industry professionals from around the globe, with new judges added in locations such as Australia, Nigeria, and the United Kingdom.

Pipe-in-Pipe by Rapid, Continuous, Smart Alloy Coating

09/2020, ARPA-E

HighT-Tech is participating in a new ARPA-E project with the University of Maryland to develop a smart alloy coating for use in pipe-in-pipe configurations with the patented high-temperature sintering process.

A novel smart alloy coating is rapidly sintered with UHS directly from the alloy powders in approximately 10 seconds. The coating can be scaled to meet commercial market demands due to its high sintering density, mechanical strength, and self-healing properties.

Advanced Catalyst Manufacturing Enabled by Direct Joule Heating

05/2020, ARPA-E

Ammonia synthesis reactions, enabled by the Haber-Bosch process, account for approximately 3% of the world’s total energy use. HighT-Tech propose a cascade reactor with a sequence of non-platinum group metals catalyst compositions tailored to a specific stage of the synthesis reaction.

HighT-Tech's novel, direct Pulse Heating process enables the synthesis of high entropy alloy nanoparticles with various catalyst compositions. This method will produce ammonia synthesis catalysts that deliver more ammonia per pass and require significantly less capital cost and energy to operate.

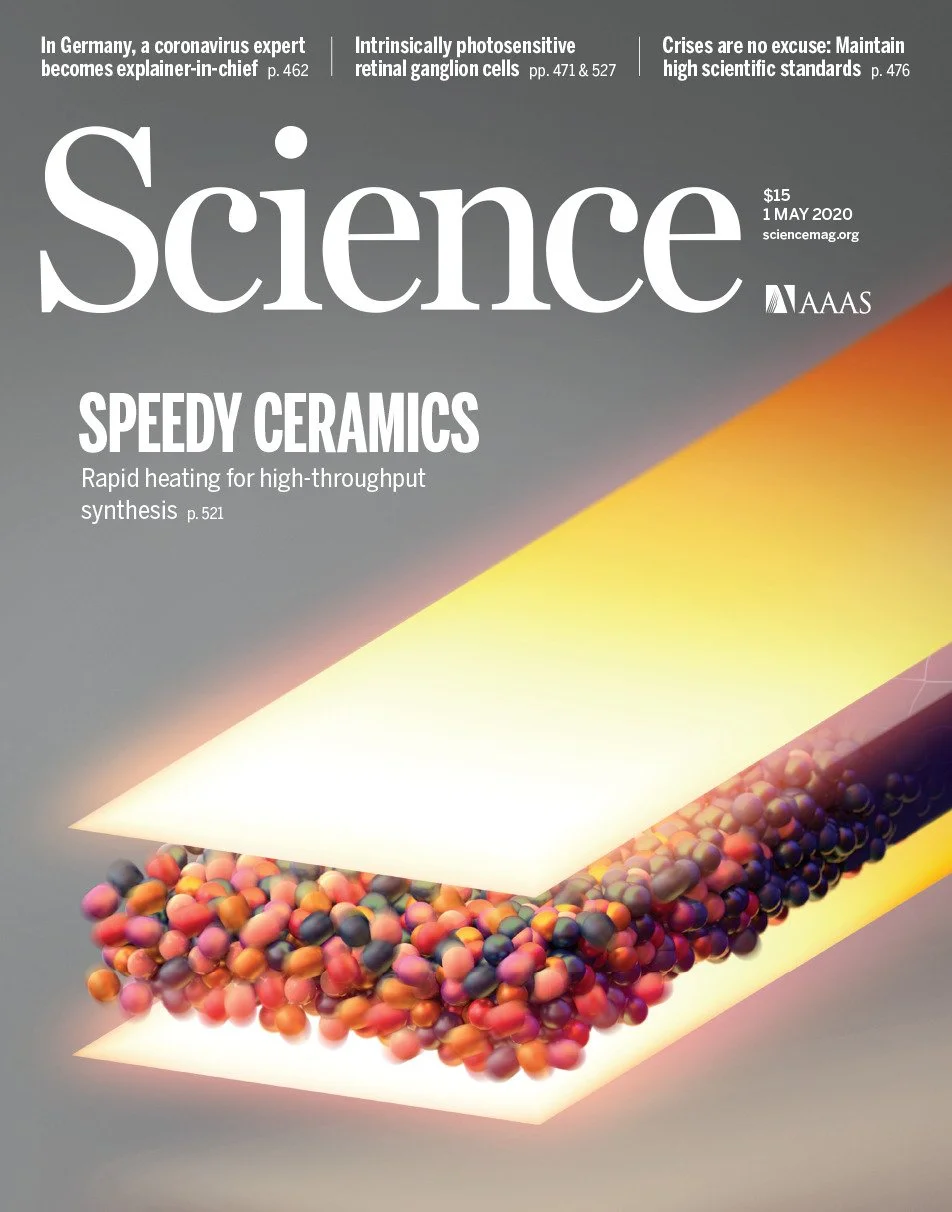

Science Cover Article on Ultrafast High Temperature Sintering (UHS)

05/2020, Science

Our paper “A general method to synthesize and sinter bulk ceramics in seconds. (Science 2020, 368, 521-526.)” led by the Co-Founder of HighT-Tech, Prof. Hu, is selected as the cover image for Science, which introduces an ultrafast high-temperature sintering (UHS) process for the fabrication of ceramic materials by radiative heating.

Science Cover Article on Pulse Heating Synthesis

03/2018, Science

Our paper “Carbothermal Shock Synthesis of High-Entropy-Alloy Nanoparticles. (Science 2018, 359, 1489–1494.)” led by the Co-Founders of HighT-Tech, Prof. Hu and Prof. Wang, is selected as the cover image for Science, which introduces a general route for alloying up to eight dissimilar elements into single-phase solid-solution nanoparticles, referred to as high-entropy-alloy nanoparticles (HEA-NPs).